Bearing Block Mounting

03/12/12 11:42 Filed in: All

I have been poking along on a lot of different projects, but back to the tail rotor shaft. Each section is a little different. The following are the measurements I settled on TRShaftDims.pdf . The holes are all now drilled and I have put it all together and am starting the final alignment procedure.

Almost done with gearboxes. Starting to look into the tail rotor.

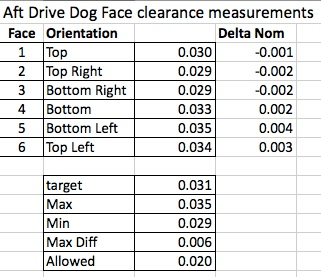

More Heli-nerd stuff: I put together the entire tail rotor driveshaft, aligned it, and re-measured the clearance between the mating drive dog faces. Two different feeler gauges were used with different combinations of fingers to average out the errors, In all cases each measurement agreed within 0.001” of each other

I am very pleased with the result at the rear. The shimming of the tail rotor gearbox is good and the drilling and fitting of the shafts didn’t change things that much. Cool. Everything is nicely centered on the nominal measurement and well under the allowed differential of 0.020”.

At the beginning of the video BJ gives you the target dimensions and at the end he sort of fudges and lets you know what you can really get away with. Happily I did not have to take advantage of the relaxed spec.

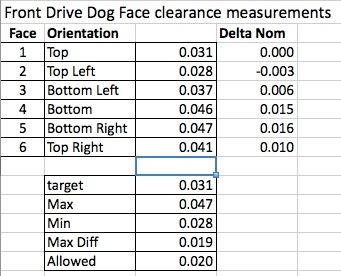

At the front shaft drive dog I got the following:

You can see that the front spacing is slightly larger and the differential is greater. The max differential is right at the (unrelaxed) spec limit. Not a lot can be done here since this is probably mostly due to the fact that the drive shaft is tilted up slightly from horizontal relative to the transmission and there is some built in twist to pre-compensate for the torquing of the frame under load. These should center out a little better when loaded, at least in the side-side differential department.

Overall I am pretty happy with this result as the distances are long and the potential for error is great. Just take your time and measure, measure, remeasure before drilling or cutting any metal.

Now, as with all other things on this machine, everything in this section gets pulled out and set aside until final assembly so I’ll be back to a stripped down frame again and my visitors will wonder if I am really doing anything other than napping in the shop.

Almost done with gearboxes. Starting to look into the tail rotor.

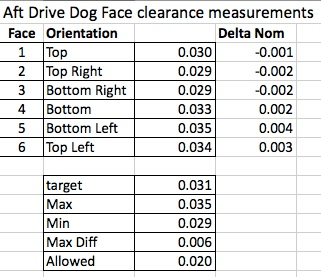

More Heli-nerd stuff: I put together the entire tail rotor driveshaft, aligned it, and re-measured the clearance between the mating drive dog faces. Two different feeler gauges were used with different combinations of fingers to average out the errors, In all cases each measurement agreed within 0.001” of each other

I am very pleased with the result at the rear. The shimming of the tail rotor gearbox is good and the drilling and fitting of the shafts didn’t change things that much. Cool. Everything is nicely centered on the nominal measurement and well under the allowed differential of 0.020”.

At the beginning of the video BJ gives you the target dimensions and at the end he sort of fudges and lets you know what you can really get away with. Happily I did not have to take advantage of the relaxed spec.

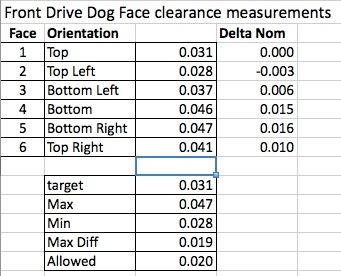

At the front shaft drive dog I got the following:

You can see that the front spacing is slightly larger and the differential is greater. The max differential is right at the (unrelaxed) spec limit. Not a lot can be done here since this is probably mostly due to the fact that the drive shaft is tilted up slightly from horizontal relative to the transmission and there is some built in twist to pre-compensate for the torquing of the frame under load. These should center out a little better when loaded, at least in the side-side differential department.

Overall I am pretty happy with this result as the distances are long and the potential for error is great. Just take your time and measure, measure, remeasure before drilling or cutting any metal.

Now, as with all other things on this machine, everything in this section gets pulled out and set aside until final assembly so I’ll be back to a stripped down frame again and my visitors will wonder if I am really doing anything other than napping in the shop.