CNC Routed Parts

01/26/15 21:43 Filed in: All

After much diddling and fiddling I am finally able to achieve a good deal of accuracy from my CNC router. While great for engraving and shaping wood, it is challenged for metal.

Fundamentally it lacks the stiffness for super-high accuracy or extremely clean cuts. It is belt driven and belts stretch. If you grab the carriage and wiggle it, you can move it back and forth maybe 10-15 mils. I have braced the metal frame, but fundamentally it is limited by that design compromise.

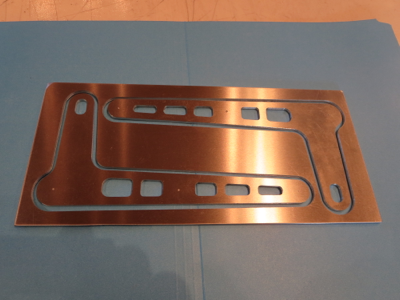

Still, for some sorts of things it is fine. I have just cut a new set of tail rotor control scissors. They are cut just as accurately as the hand cut ones I did earlier. The two pieces are nearly an exact match. The holes are drilled on the drill press as routing those holes would be insufficient accuracy. The routed slots for the steel bushings ARE at least as accurate as the hand cut ones.

I am satisfied with the results. Perhaps I will later try a new TR walking beam for pedal attach, The pieces I can fabricate are certainly straight, and light.

Old and new compared.

Fundamentally it lacks the stiffness for super-high accuracy or extremely clean cuts. It is belt driven and belts stretch. If you grab the carriage and wiggle it, you can move it back and forth maybe 10-15 mils. I have braced the metal frame, but fundamentally it is limited by that design compromise.

Still, for some sorts of things it is fine. I have just cut a new set of tail rotor control scissors. They are cut just as accurately as the hand cut ones I did earlier. The two pieces are nearly an exact match. The holes are drilled on the drill press as routing those holes would be insufficient accuracy. The routed slots for the steel bushings ARE at least as accurate as the hand cut ones.

I am satisfied with the results. Perhaps I will later try a new TR walking beam for pedal attach, The pieces I can fabricate are certainly straight, and light.

Old and new compared.