Cyclic Controls

03/26/11 18:27 Filed in: All

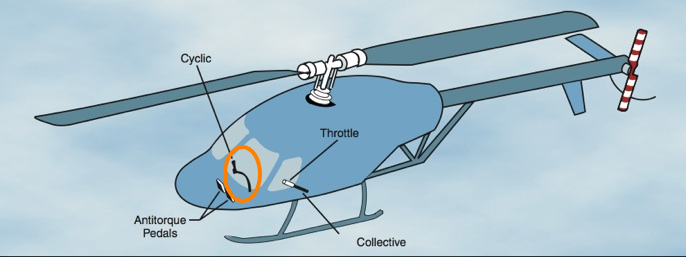

The Cyclic Controls direct fore/aft and lateral changes in force applied to the motion of the helicopter. This is probably the most complex part of the Helicycle design and as I have started to build it I am gaining appreciation for the elegant simplicity of the design employed. It’s hard to envision how it works together from pictures until you hold the parts in your hand and see the complex mixing of inputs performed. The cyclic control inputs and collective control inputs have to get mixed together before being applied to the direct rotor head controls.

Precise and careful manufacture of these subsystems will be undertaken to result in a smooth, slop-free response to operator input.

Of course having said that, the first thing I did was to break off the head of the Mic switch while trial fitting it to the handgrip. I got a couple of closest match replacements from Digikey (there are no visible vendor markings on the switch from the kit). The button head did not slide over the threads of the new switches, so I just lathed off the threads. The button head will get epoxied to the end of the new button switch.

Several hours shot finding replacements and reworking something that should have been quick.

The grip provided seems fine for me. I know a lot of folks have replaced this with something more advanced, but using the top button for flip/flop on the radio, and the trigger for the Mic should be adequate for me.

Gotta remember to keep it simple or I will be building forever.

Some sanding and smoothing is required as the grip appears to be rough cast of an epoxy resin, then 6 coats of the VHT epoxy paint hopefully will prove durable.

Cyclic stick drilled to the casting. I must say that I am amazed just how many custom castings are included in this kit.

Another mistake. The bolt fit is kind of sloppy here, like the hole is maybe 1/64 too big. I don’t know whether I grabbed the wrong bit, or didn’t have the casting clamped well enough while drilling. I will first try a “close fit” aircraft bolt and then decide whether to bump up to an AN4 bolt.

Too bad, though. The hole is nice and square and centered. It’s always something.

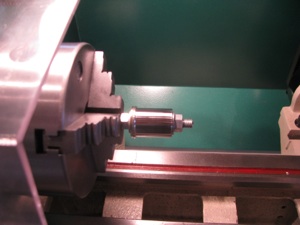

The steel plug for the front cyclic control tube was about 5-10 mils too large. Chucked it in the lathe and sanded it down a touch until it was very just very snug.

Had to sand the interior of the tube where the travel limit bracket was welded on. There were a few bumps where the tube deformed slightly while welding. Now the fit is snug, requiring just a light tap with a screwdriver handle to fit. Then I drilled the keeper bolt. Again, the mill/drill allows for a nice clean, square hole.

Cut 3/8 off the rod end and cleaned up the threads. The inner bush on the 5/16 rod end is very tight, even with additional grease. I may order some others if I can not get it to loosen up.

I agonized over how to make the holes for the safety wire/spring attach holes on the collective slider. After conjuring up many Rube Goldberg mill clamps, I ended up just free-handing it with a hand drill.

It’s a whacky angle since you definitely want to miss the interior features of the slider, but want the holes to pass through plenty of “meat” on the slider to stay strong. In both cases I was within 1/16 of my planned exit hole while drilling. Not bad. Start very small and work up very gradually, “steering” the smallest bit on the first cut.

Trial fit-up of the mixer assembly. Neat little assembly. Sanding and grease really do affect the feel, so follow the tapes closely.

My kit was different than the tape and the plans in that there is an AN4 bolt between the U-shaped wings instead of the machined allen bolt that BJ refers to. It was in the correct bag and fits properly, so I am assuming this has been updated since then.

As a diversion, before drilling the mixer to the cyclic tube, I decided to knock off the control rod fabrication. I don’t know whether the kit came this way, or I did it to myself when we moved, but the rods were all taped together with cheap packing tape that left glue all over the rods.

It took about an hour with Goof-Off to clean them all up. That stuff was persistent. Goof-Off got its name because it will make you goofy if you breathe too much of it.

Obligatory, FAA-mandated picture of me deburring control rods. I engineered the shop lighting to highlight encroaching baldness. Works pretty well, eh?

This was another one of those jobs that looks really quick, but took all afternoon and evening to clean up the rods, fit and drill the control rod end plugs into the rods.

Perhaps I was being overly anal about perfect 90 degree angles between the bolts, but that’s always been very visible to me and an indicator about the quality that may exist elsewhere on the ship. I did notice that even BJ’s bolts are not all perpendicular to each other on the construction videos.

I think it was Tim Drnec’s site showing how he welded the plugs and ground the rods so no bolts were visible at all. That’s really cool and I am sure it looks great, but a little over-the-top. I’ll live with the bolts. It’s my mantra now: “Follow the plans and finish the project. Modify later.”

Not satisfied with the freedom of the end bearings I purchased another set from Aircraft Spruce. One is the teflon race insert (type T) and the other is the plain copper insert. The plastic insert rod end is as stiff as the the one supplied by the kit. The copper insert is as smooth as butter.

I am going to replace the ones in the kit (teflon insert) with plain copper inserts for smoothness of motion. Of course the ones I got were wrong. They are MM-5 and MM-5T. BJ uses XM-5 rod ends, which are heavier duty and larger. Crazy non-intuitive numbering system. The XM versions are not available at A.S. I had to order them from Wicks. The only possible downsides might be that the metal on metal requires periodic lubrication and might possibly cause some RF interference, but seeing as he used non-teflon rod-ends for all the smaller ones this can’t be a problem.