Initial Panel Fabrication

06/03/12 16:31 Filed in: All

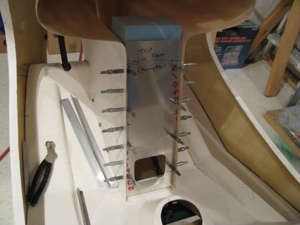

Fitting the lower instrument panel. The initial fitup is with a sacrificial aluminum sheet. Once everything is placed I will use it as a template to transfer the holes to the actual sheet to be used.

The hole is cut so I can get my hand in there and place a bracket on the pan to affix the panel on the lower edge, which should definitely strengthen things up. Screwing it in will be a pain since the cyclic riser is in the way, but not too bad with a 90 degree phillips.

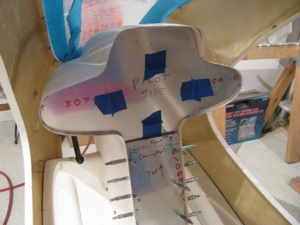

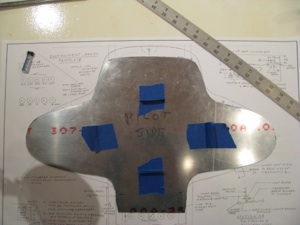

Initial cutout of the upper. This again is a sacrificial piece of aluminum. I wanted to see where I stand before messing around with the shape.

Obviously the upper instrument pod is flatter and narrower than the specified dimensions by a lot.

The drawing sheet shows an 18 3/8” width at the widest point. I am seeing almost an inch wider and and inch and a half “shorter” from the bottom to the top. I am going to have to shim the side lobes to get more vertical space and hopefully narrow it up some.

I’ll use some blue foam blocks to push the upper section up, but probably won’t get to the specified dimensions without really distorting the pod from it’s relaxed state, which I don’t want to do. The primary requirement is that the side lobes be large enough for a 3-1/8” instrument. Once that is close enough for me I will glass in the foam spacer blocks.