Jack Table

12/07/14 22:23 Filed in: All

Well, I finally finished everything I could think of on the engine prior to the mounting.

The engine went on the floor and I modified the cradle so I could just hoist it straight up and out.

Then I tried lifting the engine with my pulley system. Two problems; 1) The rope was quite stretchy. I can't imagine trying to position the engine precisely with this system., and 2) Seeing the engine dangling from a few thin strands was too nerve-wracking. That's 10-15K worth of turbine swinging on some home-depot rope.

It probably would have been fine, but between the swinging and the tough precision thing I knew I wanted to do something different.

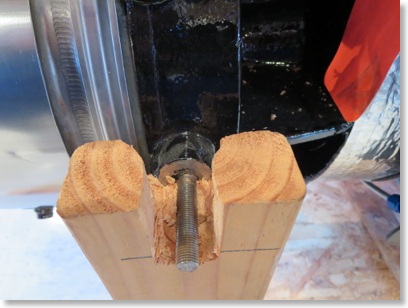

So I went to Home Depot and picked up some 3/4" threaded rod,washers, and nuts. 3/4" is certainly way overkill for the engine's weight, it's more for the stiffness so I don't need much more structure to keep the torsion and twist under control. I had a ton of MDF pieces left over from my CNC router project.

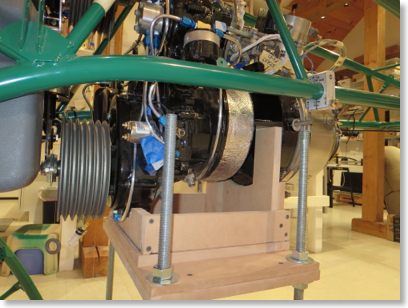

I made a new cradle for the turbine and added another thick interim layer to keep the whole thing stiff.

The idea is to transfer the turbine over to this jacking table and use the nuts to incrementally raise the engine up. Should be very safe and allow for very precise positioning.

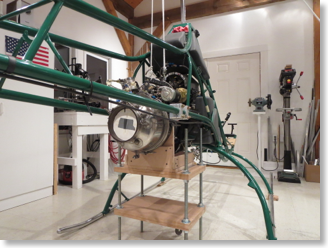

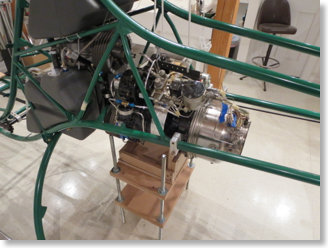

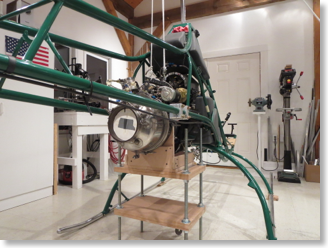

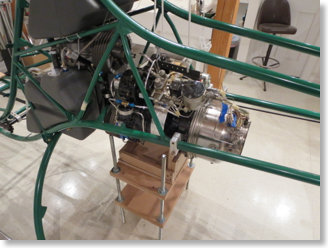

So here is the turbine in position after incrementally jacking it into position. It's very stable and certainly not going anywhere, so I can fiddle with alignment all I care to before locking it down permanently.

HERE is the whole process of building the table and jacking the turbine.

Of course after taking the photos and staring at it I realize I forgot to put the belts on so I will have to lower it a couple of inches and slide the belts on.

The engine went on the floor and I modified the cradle so I could just hoist it straight up and out.

Then I tried lifting the engine with my pulley system. Two problems; 1) The rope was quite stretchy. I can't imagine trying to position the engine precisely with this system., and 2) Seeing the engine dangling from a few thin strands was too nerve-wracking. That's 10-15K worth of turbine swinging on some home-depot rope.

It probably would have been fine, but between the swinging and the tough precision thing I knew I wanted to do something different.

So I went to Home Depot and picked up some 3/4" threaded rod,washers, and nuts. 3/4" is certainly way overkill for the engine's weight, it's more for the stiffness so I don't need much more structure to keep the torsion and twist under control. I had a ton of MDF pieces left over from my CNC router project.

I made a new cradle for the turbine and added another thick interim layer to keep the whole thing stiff.

The idea is to transfer the turbine over to this jacking table and use the nuts to incrementally raise the engine up. Should be very safe and allow for very precise positioning.

So here is the turbine in position after incrementally jacking it into position. It's very stable and certainly not going anywhere, so I can fiddle with alignment all I care to before locking it down permanently.

HERE is the whole process of building the table and jacking the turbine.

Of course after taking the photos and staring at it I realize I forgot to put the belts on so I will have to lower it a couple of inches and slide the belts on.