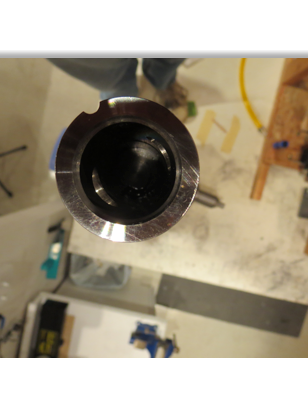

Main Shaft Plug

03/22/14 23:35 Filed in: All

Well ahead of the transmission installation video in the rotor head video, BJ mentions how the main shaft should be plugged to keep out moisture. First up was to slather a goodly amount of Corrosion-X in the shaft after a few acetone swipes. Then I lathed up an ABS plug that was snug, but not even really "tap tight". Once parted the plug is only about an inch long.

The plug was coated with 5-minute epoxy and slid down inside the tube. I measured the steel main drive plug that slides inside the shaft, then I pushed the moisture plug down plenty far enough to clear the plug when it is installed. While the epoxy was setting up I wiped and cleansed the inside of the tube above the plug with acetone to remove any trace of the epoxy so the drive plug will not be fouled when it is inserted.

The edges of the hole for the drive pin are sharp, sharp, sharp, and I cut the hell out of my finger while swabbing out epoxy. Nice mixture of acetone and epoxy now coursing through my bloodstream. About every two weeks I will cut a finger, grind myself or otherwise accumulate minor scar tissue on this project.