Tail Rotor Shaft Start

02/06/12 11:20 Filed in: All

Started on the tail rotor and drive shafts. First task is to mount the TR gearbox. Off and on about a dozen times with lots of little trimming with the a rat tail file to open up the mounting holes. Nice and snug with no play when tightened down. The angle between the main mast and the TR shaft is about 89.5 degrees. BJ says less than a couple of degrees is OK, so there is no need to bugger up the mounting holes by trying to achieve a perfect 90. Better to keep them tight and live with the very minor angular misalignment.

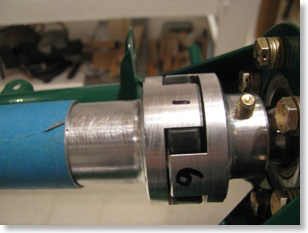

Shaft sections are cut and first order fitting completed. A lot of fiddling required to get the lengths right. Fit is very tight over the bearing inserts, so it takes some sanding/polishing and a daub of grease to get them to slide on. That will be mostly removed on final assembly. There is a definite sequence of assembly required. Start at the front since the bearing blocks all mount from the rear.

Small cuts and sanding, then retry. Very time consuming.

To get the TR gearbox aligned required a thick washer on the bottom and a thin in the middle, and none at the top on the outside of the frame between the gearbox and the frame. This is almost the opposite of what BJ required in the video. Like his example, almost no left/right differential was required, mostly up/down.

At the TR gearbox the distance between the dogs and the mate is measured. The goal is less than 0.020 differential side-side or up/down. I numbered the ears and measured the following:

1 - 0.030, 4 - 0.029 delta = 0.001

2 - 0.025, 5 - 0.035 delta = 0.010

3 - 0.024, 6 - 0.034 delta = 0.010

It is numbered this way because measurements 1 and 4 are on opposite sides, 2-5 are opposite, and 3-6 are opposite. The greatest difference is 0.011 between any two and there is definitely less than 0.020 difference, so I am satisfied (almost). I may try to add my thinnest shim stock to the 3 right side bolts to try to remove the slight CCW cant (viewed from top) and get it as close to perfect as possible. Now is the time as it’s unlikely I will revisit this until final assembly.

Shaft sections are cut and first order fitting completed. A lot of fiddling required to get the lengths right. Fit is very tight over the bearing inserts, so it takes some sanding/polishing and a daub of grease to get them to slide on. That will be mostly removed on final assembly. There is a definite sequence of assembly required. Start at the front since the bearing blocks all mount from the rear.

Small cuts and sanding, then retry. Very time consuming.

To get the TR gearbox aligned required a thick washer on the bottom and a thin in the middle, and none at the top on the outside of the frame between the gearbox and the frame. This is almost the opposite of what BJ required in the video. Like his example, almost no left/right differential was required, mostly up/down.

At the TR gearbox the distance between the dogs and the mate is measured. The goal is less than 0.020 differential side-side or up/down. I numbered the ears and measured the following:

1 - 0.030, 4 - 0.029 delta = 0.001

2 - 0.025, 5 - 0.035 delta = 0.010

3 - 0.024, 6 - 0.034 delta = 0.010

It is numbered this way because measurements 1 and 4 are on opposite sides, 2-5 are opposite, and 3-6 are opposite. The greatest difference is 0.011 between any two and there is definitely less than 0.020 difference, so I am satisfied (almost). I may try to add my thinnest shim stock to the 3 right side bolts to try to remove the slight CCW cant (viewed from top) and get it as close to perfect as possible. Now is the time as it’s unlikely I will revisit this until final assembly.