Initial Transmission Fit

01/14/12 00:09 Filed in: All

Hooray! Transmission preliminarily in place. That’s a piece of 2” PVC pipe, which fits perfectly to protect the shaft while sliding into position. This is definitely a 2 person operation.

Once in place I clamped a piece of wood underneath the transmission so I can lower it a few inches to clear the tabs when needed.

Ran the alignment string and rough set the pre-load offset angle (very precise twist/measure/clamp/repeat).

The undrilled side tab was not exactly parallel, so it had to be bent down about 0.75degree.

When the pre-drilled bolt was snugged, the first to bottom was the undrilled side. It also looks like the inner side of the tab touches first. I could either make an angled shim or perhaps take a touch of aluminum off the casting. I don’t want to stress the tab welds by trying to impart a twist in the steel tab.

With the undrilled (right) side bottomed there’s a 63 mil gap between the left-side side tab and the casting. The photo also makes it look like they are not parallel. I’ll double check to make sure this is not a trick of the camera lens.

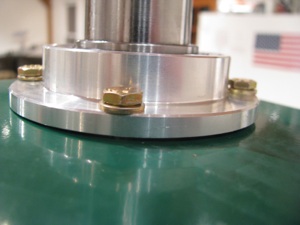

With everything jigged and clamped you can see the uneven gap at the hood bearing. It’s maybe 0.040” at its largest which is exactly on the right side of the ship. I think much of this is probably due to the built-in slight leftward tilt of the mast. I’ll work the main mounts before worrying to much about this.

I can judge the left/right tilt of the main mounts by making sure this bearing housing slides up and down easily when the main mounts are in position and clamped. I guess the fore-aft tilt of the main transmission is locked in place by the lift strut. I’ll have to play with that a bit. I will probably diddle around with this for a few hours to make sure every angle and clearance is understood and addressed before making permanent changes (ie: drilling that undrilled tab and the lift strut mount). Mistakes here would be difficult to fix and very expensive.